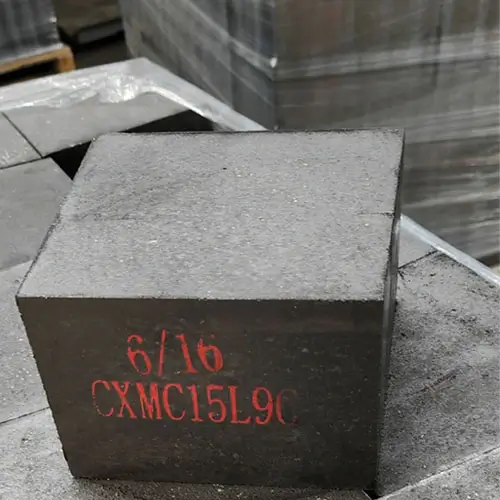

The main raw materials used in the production of MgO-C bricks are magnesia aggregate, graphite, resins, and other additives. Magnesia-carbon (MgO-C) refractory is important and widely used refractory in the steelmaking. It is characterized by a reduced slag infiltration depth and a high thermal shock resistance due to its carbon (C) content. Applications of this refractory not only include wear linings in basic oxygen furnace (BOF), electric arc furnace (EAF), and steel ladle, but also functional products such as purging and taphole bricks. The success of the use of basic MgO-C refractory in the steelmaking is based on its good properties of resistance to erosion, corrosion, and thermal shock.

Magnesia Carbon brick Advantages:

1.Good high temperature resistance

2.Strong anti-slag penetration resistance

3.Resistance to thermal shock

4.High Corrosion resistance to slag

5.Non-Wettability to molten slag

6.Increases lifespan of the vessal.

7.Low thermal expansion

MgO-C brick is a composite material based on MgO.These bricks show excellent resistance to thermal shock and corrosion at eleveted temperatures.MgO-C bricks are used extensively in Steel industry. Magnesia carbon bricks are mainly used for the lining and tapping port of steelmaking oxidation converter, the hot spot of high-power electric furnace wall, refining furnace lining, the slag line of steel barrel, etc.

Magnesia Carbon Brick Features:

- Excellent resistance in slag abrasion

- Higher temperate resistant with good refractoriness

- lower creep in high temp

- Good thermal shock resistance performance

- Lower apparent porosity

- not easily wet with slag

Reviews

There are no reviews yet.