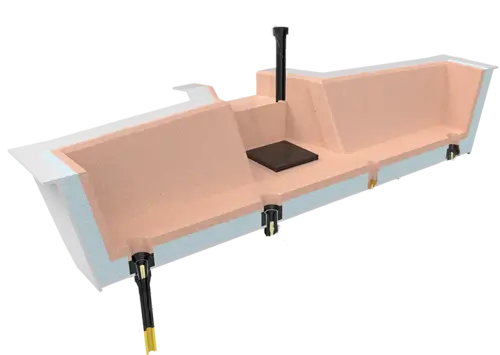

Common insulation materials for tundish

The refractory materials of the tundish include permanent layer castables, working layer dry materials, nozzles and seat bricks, slag retaining wall series and continuous casting.

The permanent layer is between the working layer and the tundish shell, and is not in direct contact with the molten steel and slag. It mainly plays the role of heat insulation and protection of the cladding. Generally, aluminum-magnesium castables are used.

The working layer is in direct contact with the molten steel and slag, and needs to withstand the erosion of the molten steel, erosion and penetration of the slag. The working layer mostly uses magnesium dry materials, which have good slag resistance, are easy to construct, easy to disassemble, and can also purify the molten steel.

The tundish nozzle is the channel for the molten steel to enter the crystallizer from the tundish, and needs to withstand the erosion of the molten steel and the rapid change of temperature; the seat brick plays the role of protecting and fixing the nozzle, and does not come into direct contact with the molten steel. The tundish nozzle is mostly composed of a zirconium core and a high-aluminum billet, and the seat brick is generally made of high-aluminum material.

The slag retaining wall series refractory materials mainly include slag retaining walls, side plates, back plates and turbulators, which need to withstand the scouring of molten steel, erosion and penetration of slag. They are generally made of magnesium materials.

The three major parts of continuous casting include large package sleeves, stopper rods and immersed nozzles, which need to be flushed with molten steel, eroded and penetrated by slag. The stopper rod is used to control the flow of molten steel during pouring, and the large package sleeve and immersed nozzle are used to protect the pouring, isolate the air, and prevent the secondary oxidation of molten steel. The three major parts of continuous casting are mostly made of aluminum carbon, and sometimes some zirconium oxide is added.

Common problems and solutions

Some of the problems that arise during the use of tundish refractory materials are quality issues of the materials themselves, while others are related to on-site construction and require careful observation and analysis.

1.Dry material has no strength

Before the tundish is put into use, the dry material in the working layer needs to have a certain low-temperature strength, which is mainly obtained by vibration and baking. After the dry material is demolded by vibration and baking, it often has local strengthlessness or low strength, which can easily cause the tundish to collapse and affect the production of continuous casting. After long-term observation and analysis, it is found that the main reasons for the lack of strength or low strength of the dry material are:

(1) Baking problem: The tundish baking device used in the steel plant is a gas baker. After long-term use, it will cause a large amount of tar to accumulate in the pipeline or the burner to be damaged, resulting in poor local baking effect and lack of strength or low strength.

(2) Dry material is damp: Dry material is composed of 70% granules and 30% fine powder. Fine powder contains magnesia and binder. Fine powder is easy to absorb water and damp due to its high specific surface area. Magnesia and binder will be hydrated and deteriorate after absorbing water, resulting in the failure of binder and failure to generate bonding strength during baking;

(3) Uneven mixing of binder: When producing dry material, various granules, fine powder and binder need to be mixed together evenly. Sometimes, due to human factors or mixing equipment, the mixing is uneven. Some dry materials have no binder or the binder content is very low, resulting in local lack of strength after baking and demolding.

Solution: First, it is necessary to ensure the baking effect of the baking machine, regularly purge the gas pipeline, remove tar and dust, and replace damaged burners in time. Secondly, it is necessary to ensure that the dry material is dry and the mixing is uniform.

2.Turbulator Up

Turbulators mainly play the role of stabilizing steel flow and protecting the impact zone during continuous casting. They belong to the slag retaining wall series of refractory materials and are generally produced with magnesium materials. During the multi-furnace continuous casting process, turbulators sometimes float on the surface of molten steel, which cannot stabilize the steel flow and protect the impact zone, which is detrimental to the quality of molten steel and safe production. The turbulator floats because the density of the refractory material is less than the density of molten steel, and it will float when immersed in molten steel. The turbulator floats up, including the turbulator frame floating up and the overall floating up. The turbulator frame floats up because the magnesium material has a large expansion coefficient when immersed in high-temperature molten steel, which is easy to cause cracking, and the contact part between the frame and the impact plate is a weak link, which is easy to cause the frame and the impact plate to separate. The overall floating is because the bottom working layer is uneven when the turbulator is installed. After pouring, the molten steel drills into the gap between the turbulator and the working layer, causing the turbulator to float up as a whole.

Solutions: The first is to adjust the formula of the turbulator to control the expansion under high temperature; the second is to spread a layer of refractory powder on the surface of the working layer when installing the turbulator to ensure that there is no gap between the turbulator and the working layer.

3.Nozzle cracking and steel seepage

The tundish nozzle containing zirconium core is prone to cracking during the pouring process, resulting in steel seepage, which often forces continuous casting to block flow or abnormal shutdown. Analysis shows that the cracking of the nozzle is mainly due to the poor thermal shock resistance of the zirconium core.

Solution: The volume density of the zirconium core cannot be too high. The higher the volume density, the worse the thermal shock resistance. Appropriately thickening the nozzle blank can prevent the steel liquid from seeping out.

Tundish Furnace

4.Large package casing broken

The ladle casing is located between the ladle outlet and the tundish. Its metallurgical function is to prevent the molten steel from splashing and being oxidized during the process of flowing from the ladle into the tundish. The most common problem of the ladle casing during use is breakage. There are two reasons for the breakage. One is that the ladle casing has poor thermal shock resistance. The other is that when replacing the ladle, the ladle casing and the ladle outlet need to be separated. When the casing and the ladle outlet are tightly attached, the steel pouring worker applies external force to the ladle casing, causing the casing to break.

Solutions: First, use materials with small thermal expansion coefficients and elastic molds to produce casings to improve thermal shock resistance; second, when the casing and the outlet cannot be shared, no external force can be applied to the lower part of the casing. External force can be applied to the upper steel shell of the casing to separate it.