Slide gate plate plays an important role in the ladle system, and it is very important to improve service life of ladle slide gate. Learn methods to increase service life of ladle slide gate and the functions of ladle slide gate.

Slide gate plate is the most important part among the slide gate nozzle system, which directly control the flow of the molten steel. Due to long time contact with high temperature molten steel and frequently strong heat impact, it easily got spoiled.

Following are some solutions that could promote slide gate plate service life.

1.Types of slide gate plate

It is better to use the alumina- carbon based slide gate plate, which has a good erosion and strong thermal shock resistance. Bonded with carbon material, this type of slide gate characterized with high thermal conductivity and low thermal expansion coefficient.

2.Installation of slide gate plate

Make sure the fire mortar has a suitable proportion, mixed well and suitable proportion and no impurities. Never use the dried and lumpy mortar. It is also not acceptable to mix the new mortar with the used one. Make sure the upper nozzle is clean, no any residue in slide gate frame and sliding mechanism. Before installation, make sure the slide gate are not deformed or cracked. Keep the slide gate steady and smooth during the installation, and check whether there is any bump and swing after installation.

3.Using of slide gate plate

It is better to adapt auto cast program when casting steel, do not frequently and drastically open or close the slide gate. Once in need of burn oxygen, the slide gate plate must be fully opened and discharge the slide gate sand as much as possible.

4.Selectright slide plate material

The refractory material used in the slide gate plate must be compatible with the chemistry of cast steel grade. The calcium concentration in the steel is important when selection of the slide plate material is made. The material of the slide plate is also dependent on the sliding stroke length of the plate. For smaller plates, magnesia-based materials are preferred whereas, and for bigger plates, alumina-based materials are used. The slide plate is subjected to high throttling as well. Therefore, a suitable plate material with a suitable bonding system has to carefully chosen keeping in mind the various factors involved in the process.

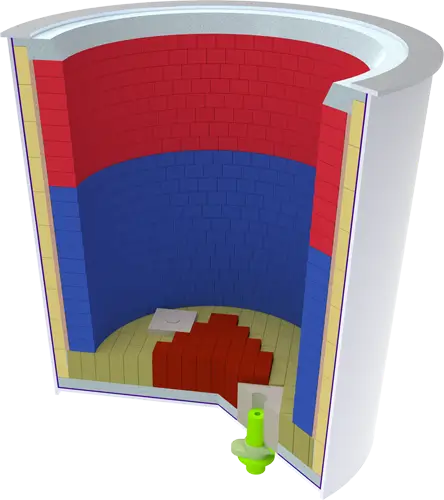

The ladle slide gate system is acritical piece of flow controlequipment in liquid steel cast-ing. The service life of the slidegate plate is a limiting factor toachieve performance and isgreatly dependent on the typeof slide gate mechanism used.

The function of the ladle slide gate system

The primary function of the ladle slide gate system is to control the flow of the liquid steel from the ladle to the tundish. It has been observed that the life of slide gate plates is the bottleneck which accounts for inferior performance of the overall slide gate refractory system. The performance of the slide gate plate is dependent on many factors such as refractory material, operating conditions, steel grade and slide gate mechanism.

The characteristic features of the ladle slide gate are as follows:

safety and reliability

simplicity and robustness

higher stroke length

automatic face pressure loading

outboard spring design

optical configuration,

plate crack control

higher face pressure

lower nitrogen pick-up

increased plate life

The main tasks of the slide gate system

Adjust the steel flow from the ladle to the tundish

Minimize the risk of steel re-oxidation

Efficient management of ladles during steel production

Different Types of Ladle Slide Gate Plates

- High aluminum slide gate plate

- Aluminum carbon slide gate plate

- Aluminum-zirconium carbon slide gate plate

- Magnesia carbon and spinel carbon slide gate plate

In summary,ladle slide gate system is acritical piece of flow controlequipment in liquid steel cast-ing. Welcome to learn methods to increase service life of ladle slide gate and the functions of ladle slide gate. Visit our factory to view more refractory products.

More details about Ladle Slide Gate Plate

What is slide gate in ladle?

The function of a ladle slide gate system is to precisely control the steel flow from the ladle to the tundish.

What is the use of slide gate plate?

Slide Gate Plate Refractories are installed on the ladle’s bottom for regulating the flow of liquid steel from Ladle to Tundish. These are special refractories and should be treated with caution. Failure could lead to a severe catastrophe.

What are ladle slide gate plates made of?

Aluminum-zirconium carbon slide gate plate. The slide plate of this material uses low expansion rate of Al2O3-SiO2-ZrO2 raw materials, made into a refractory material characterized by carbon bonding with oblique zircon, mullite, corundum, etc.