The heating temperature of the electric furnace depends on the material and power of the heating element. Generally speaking, the heating temperature of the electric furnace can reach more than 1000℃, and if the high temperature alloy material is used to make the heating element, it can even reach a high temperature of more than 1500℃. Resistance type electric furnace. The usual temperature range is from room temperature to 1200℃.

Electric furnaces are generally categorized as follows:

Tubular electric furnaces. The temperature range is generally from room temperature to 1600°C.

Induction Furnaces. The temperature range is generally from room temperature to 2500℃.

Hot air circulation furnace. The temperature range is generally room temperature to 300℃, some high-end models can be heated to more than 500℃.

High temperature electric furnace. The temperature range is generally around 1000℃, some high-end models can even reach 3000℃ or more.

Industrial electric furnace. The temperature range is generally above 1000℃, and the highest can be heated to thousands of degrees Celsius.

High temperature furnace. General use of the temperature range of 1000 ℃ to 2000 ℃.

Vacuum furnace. General use of the temperature range of 800 ℃ to 1800 ℃.

Atmosphere furnace. General use of the temperature range of 400 ℃ to 1200 ℃.

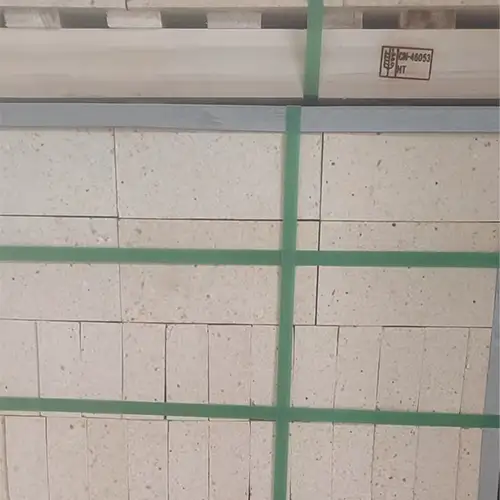

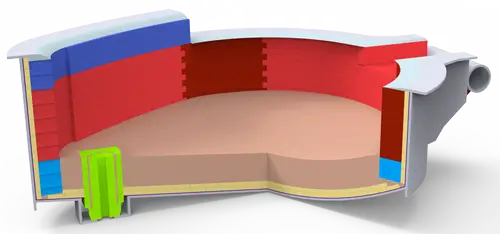

Primary high alumina bricks are characterized by the following main aspects:

1.Slag resistance: the first grade of high alumina brick in Al2O3 more, close to the neutral refractory materials, can resist the erosion of acidic slag and alkaline slag.

2.Refractoriness: the refractoriness of high alumina bricks is higher than that of clay bricks and semi-silica bricks, reaching 1750~1790℃, which belongs to advanced refractories.

3.Load softening temperature: because of the high Al2O3 in high alumina products, less impurity mass, the formation of fusible glass body less, so the load softening temperature is higher than the clay brick.

4.Abrasion resistance: high alumina bricks have better abrasion resistance.

5.Impact resistance: good impact resistance, long service life.

6.High compressive strength at room temperature and high temperature.

7.Thermal shock resistance: the ability to resist rapid changes in temperature without being destroyed is stronger.

Secondary high alumina bricks are alumino-silicate refractories with Al2O3 content of 60%~75%, whose main components are alumina and silicon oxide, and also contain a certain proportion of clay, quartz sand and other minerals.

The following are the characteristics of secondary high alumina bricks:

1. High refractoriness: the refractoriness of secondary high alumina bricks is generally above 1700°C, and the high load softening temperature can reach above 1400°.

2. Good abrasion resistance: high alumina bricks have better abrasion resistance and long service life.

3. good slag resistance: high alumina bricks with more Al2O3, close to neutral refractories, can resist the erosion of acidic slag and alkaline slag.

4. Good thermal stability: high alumina bricks have better thermal shock resistance and good thermal shock stability.

5. High temperature strength: low high temperature creep rate, high temperature strength and other characteristics.

Tertiary high alumina bricks have the following advantages:

High refractoriness: up to 1750-1790 degrees, it belongs to middle and high grade refractory materials, which are more widely used in all kinds of furnaces.

High loading softening temperature: Because of the high content of AI2O3 in high alumina products, less impurities, less fusible glass crystals formed, so the loading softening temperature is high.

Strong slag resistance: high alumina bricks belong to neutral refractories, which can resist acidic gas or slag, and can also resist alkaline gas and slag erosion.

High thermal stability: tertiary high alumina bricks are made of bauxite or other raw materials with high alumina content by molding and calcining, which have good high-temperature strength, high-temperature creep resistance, thermal shock resistance and erosion resistance.

Good flexibility: the flexibility of the three-stage high alumina brick is relatively good, the outer layer can be used as a thermal insulation layer, the use of high alumina heat-insulating refractory bricks to keep the temperature down, while reducing the temperature of the outer wall of the steel shell.