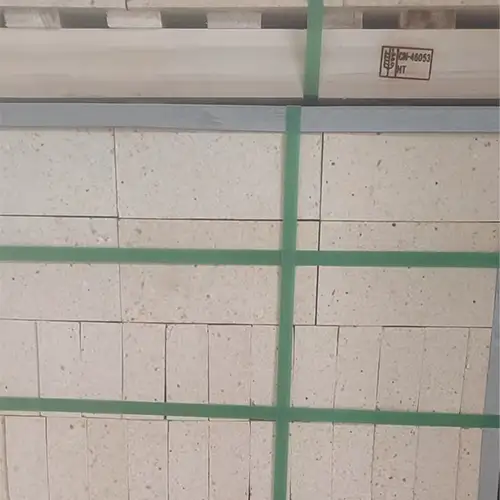

High Alumina Bricks are produced with select bauxite chamotte as main raw material, fired at 1450-1470 °C by advanced process with strict quality control. High Alumina bricks have great features like high temperature performance, great corrosion and wear resistance, high bulk density, low iron content, etc. High Alumina bricks are extensively used in mining, metallurgy, cement, and chemical, refinery and refractory industries. These bricks are used in all kinds of industrial furnaces and high temperature areas to prolong the lives of furnaces.

High Alumina Bricks Properties:

High refractoriness: With melting points exceeding 1770°C (3218°F), these bricks can withstand intense heat without deforming.

Excellent thermal shock resistance: They can endure rapid temperature changes without cracking or spalling.

Superior mechanical strength: They maintain structural integrity even under heavy loads and thermal stress.

Chemical stability: Resistant to corrosion from acids, alkalis, and other harsh chemicals.

Low thermal conductivity: Minimizes heat transfer, making them efficient insulators.

High alumina brick Refractoriness is higher than Clay brick and semi-silica brick,reaching 1750~1790℃,it’s the advanced refractory materials.

High Alumina Bricks Advantage

1. High temperature creep rate

2. Strong erosion resistance

3. Thermal shock stability

High alumina bricks play a vital role in industries requiring materials capable of withstanding extreme temperatures and harsh conditions. Understanding their properties, applications, and maintenance requirements is essential for maximizing their performance and longevity in various industrial settings. Incorporating high alumina bricks into infrastructure and equipment not only ensures operational efficiency but also contributes to enhanced safety and reliability across diverse industrial sectors. Whether in steelmaking, cement production, or petrochemical processing, these bricks remain indispensable for facilitating critical operations and infrastructure development worldwide.

Reviews

There are no reviews yet.