(1) Refractories for ARC furnace roof

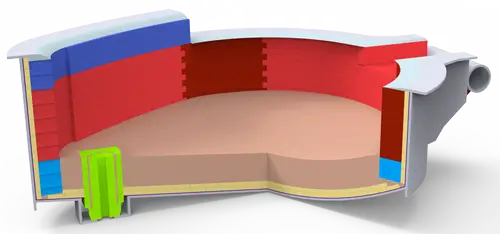

Electric Arc Furnace life refers to the life of furnace roof. After the 1980s, with the expansion of steel-making electric arc furnace capacity and the increase of unit power, the working conditions of the furnace roof become more demanding, the refractories used for electric Arc furnace also changed.

The roof of arc furnace commonly use high alumina brick to masonry, Al2O3 content of between 75% to 85%. Compared with silica brick, the characterized of high alumina brick is high refractoriness, thermal shock resistance, good slag resistance, high compressive strength. Because of its high thermal shock resistance and structural integrity, it is not necessary to produce shaped bricks. There ie a rich bauxite resources in China, high alumina brick has become the main refractory material on Arc Furnace roof, its life is 2 to 3 times of silica brick roof . With the development of large-scale ultra-high-power electric furnace, the service life of high-alumina brick is reduced, Leading to the further use of calcined or not burning magnesia brick and magnesia-chrome brick and other alkaline brick.

(2) Refractories for ARC furnace wall

The furnace wall is divided into general furnace wall, slag line area and hot spot that near the arc . The main furnace wall mainly uses the magnesia brick, the tar pitch combination and the asphalt impregnation burns the dolomite brick and the magnesite brick masonry, also has uses does not burn the magnesia alkaline brick and the asphalt union magnesia and the dolomite ramming material, That all have longer service life. ARC furnace wall which Ultra-high power or smelting special steel used the magnesia-chrome brick and high-quality magnesia brick to masonry.

Slag line area and the hot spot of furnace wall is weak link. As the furnace wall life depends mainly on the degree of damage of hot spot, so the parts of lining should be special attention. the 20th century 70 years ago, the masonry of the site commonly used cast magnesium chrome bricks, combined with or re-combination of magnesia- chrome brick, the service life is 100 to 250 furnace times. Into the 80’s, in these parts widely used Mg-C brick to masonry, showing that in addition to high temperature and slag resistance performance,service life be significantly improved , the high-power electric arc furnace to more than 300 times in China.

In order to make balance the damage of the furnace wall and prolong the service life, furnace wall is also used inlaid water cooling box or water cooling measures. The inner surface of the furnace is sprayed with a layer of fire-resistant coating to make the dross form a protective layer, which can reduce the unit consumption of the refractory material. effectively. But the energy consumption is relatively increased.

(3) Refractories for bottom of electric ARC furnace

Knotted lining use good sintered magnesia or fused magnesia, there is working lining and permanent lining under the ramming layer.The working lining use tar pitch bonded magnesium bricks magnesia brick, and permanent lining is generally use magnesia brick. The slag line parts upper the dike slag line parts,as slag erosion is serious,now more use the lining brick what same or similar the furnace wall hot spots,such as casting magnesia-chrome brick or re-combination magnesia-chrome brick. The effect is better when use of magnesia carbon brick, the service life can be as high as 100 to 200 furnace times.

The anode end of the direct current electric arc furnace is connected with the contact piece of the furnace bottom, the bottom of furnace use thermal conductivity refractory material or metal components to solve the problem of conduction, the main requirements of the conductive refractory is low resistance (10-4 ~ 10-2 Omega . m) and the resistance must be stable, usually using combination asphalt with resin ,magnesia-carbon bricks having a carbon content of preferably 10% to 18% are used as the conductive refractory, and include permanent lining, working lining and a protective coating. Working lining use magnesia ramming compound.

(4) Refractories for taphole

In 1980s, the advantages of tapping port are: The tilting electromechanical equipment has been canceled, the area of the water-cooling wall has been expanded, the damage of lining has been eased, the temperature of tapping steel can be reduced and the time of tapping can be reduced, thus reducing investment and saving electric energy. people use resin-bonded magnesia-carbon brick as taphole bricks, magnesia carbon brick as tube brick, and people use magnesia carbon brick or Al2O3-C-SiC brick as end brick. In order to make the melton steel flow out more successfully, usually people use olivine-based coarse sand as drainage material.